本应用笔记介绍一种采用 dsPIC ® 数字信号控制器

(Digital Signal Controller, DSC)或 PIC24 单片机来实现无刷直流 (Brushless Direct Current, BLDC)电机无传感器控制的算法。该算法利用对反电动势(Back-Electromotive Force,BEMF)进行数字滤波的择多函数来实现。通过对电机的每一相进行滤波来确定电机驱动电压换相的时刻。这一控制技术省却了分立的低通滤波硬件和片外比较器。需指出,这里论述的所有内容及应用软件,都是假定使用三相电机。该电机控制算法包括四个主要部分:

• 利用 DSC 或单片机的模数转换器(Analog-to-Digital Converter,ADC)来采样梯形波 BEMF 信号

• PWM 导通侧 ADC 采样,以降低噪声并解决低电感问题

• 将梯形波BEMF信号与V BUS /2进行比较,以检测过零点

• 用择多函数滤波器对比较结果信号进行滤波

• 以三种不同模式对电机驱动电压进行换相:

- 传统开环控制器

- 传统闭环控制器

- 比例 - 积分(Proportional-Integral,PI)闭环

控制器

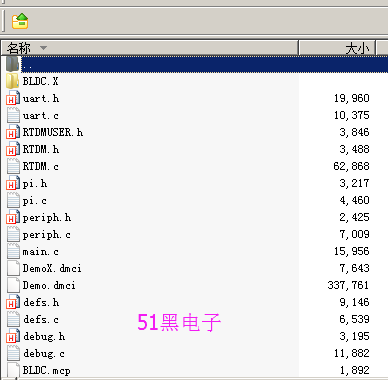

单片机源程序如下:

- /************************************************************************************************************************

- * ?2011 Microchip Technology Inc.

- *

- * MICROCHIP SOFTWARE NOTICE AND DISCLAIMER:

- *

- * You may use this software, and any derivatives

- * created by any person or entity by or on your behalf, exclusively with Microchip抯 products.

- * Microchip and its licensors retain all ownership and intellectual property rights in the

- * accompanying software and in all derivatives hereto.

- *

- * This software and any accompanying information is for suggestion only.

- * It does not modify Microchip抯 standard warranty for its products. You agree that you are

- * solely responsible for testing the software and determining its suitability.

- * Microchip has no obligation to modify, test, certify, or support the software.

- *

- * THIS SOFTWARE IS SUPPLIED BY MICROCHIP "AS IS". NO WARRANTIES, WHETHER EXPRESS, IMPLIED OR STATUTORY,

- * INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF NON-INFRINGEMENT, MERCHANTABILITY, AND FITNESS FOR

- * A PARTICULAR PURPOSE APPLY TO THIS SOFTWARE, ITS INTERACTION WITH MICROCHIP扴 PRODUCTS, COMBINATION WITH

- * ANY OTHER PRODUCTS, OR USE IN ANY APPLICATION.

- *

- * IN NO EVENT, WILL MICROCHIP BE LIABLE, WHETHER IN CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE OR BREACH

- * OF STATUTORY DUTY), STRICT LIABILITY, INDEMNITY, CONTRIBUTION, OR OTHERWISE, FOR ANY INDIRECT, SPECIAL, PUNITIVE,

- * EXEMPLARY, INCIDENTAL OR CONSEQUENTIAL LOSS, DAMAGE, FOR COST OR EXPENSE OF ANY KIND WHATSOEVER RELATED TO THE SOFTWARE,

- * HOWSOEVER CAUSED, EVEN IF MICROCHIP HAS BEEN ADVISED OF THE POSSIBILITY OR THE DAMAGES ARE FORESEEABLE. TO THE FULLEST

- * EXTENT ALLOWABLE BY LAW, MICROCHIP'S TOTAL LIABILITY ON ALL CLAIMS IN ANY WAY RELATED TO THIS SOFTWARE WILL NOT EXCEED

- * THE AMOUNT OF FEES, IF ANY, THAT YOU HAVE PAID DIRECTLY TO MICROCHIP FOR THIS SOFTWARE.

- * MICROCHIP PROVIDES THIS SOFTWARE CONDITIONALLY UPON YOUR ACCEPTANCE OF THESE TERMS.

- ***********************************************************************************************************************/

- #include "defs.h" //defines, function headers, pi, etc

- #ifdef RTDM_DEMO

- #include "debug.h" //RTDM/DMCI functionality

- #endif

- int main(void)

- {

- Init_Ports(); // Clock ( Fcy 70MHz ) , port configuration, etc

- #ifdef RTDM_DEMO

- DBG_Init(); // RTDM ( Debugger ) Initialization

- #endif

- //defaults: CLKW rotation, motor stopped

- Flags.RunMotor = 0;

- Flags.Startup = 0;

- Flags.CLKW = 1;

- Flags.newCLKW = 1;

- Flags.DMCI_Control_SW = 0; //default potentiometer read

- Timer2Average = TMR2_MAX;

- trigger_count = 1;

- Flags.nb_delay_on = 0;

- #ifdef OPEN_LOOP_CONTROL

- DesiredDuty = MIN_DUTY_CYCLE;

- #else

- DesiredRPM = STARTUP_RPM;

- #endif

- Flags.current_state = STATE_STOPPED;

- while(1) {

-

- if(S2) { //CLKW/CCLKW switch

- while(S2) //debounce

- Delay_100uSec(DEBOUNCE_DELAY*10);

- Flags.newCLKW = !Flags.CLKW;

- }

- if(S3) { //start/stop switch

- while(S3) //debounce

- Delay_100uSec(DEBOUNCE_DELAY*10);

- if(Flags.current_state == STATE_STOPPED)

- Flags.current_state = STATE_STARTING;

- else

- Flags.current_state = STATE_STOPPING;

- }

- switch(Flags.current_state) {

- case STATE_STOPPING:

- Stop_Motor();

- Flags.current_state = STATE_STOPPED;

- break;

- case STATE_STARTING:

- //startup done on MCPWM ISR

- break;

- case STATE_FAULT:

- Stop_Motor();

- Flags.current_state = STATE_STOPPED;

- break;

- case STATE_STARTED:

- if(Flags.newCLKW != Flags.CLKW) {

- Stop_Motor();

- Flags.CLKW = Flags.newCLKW;

- Delay_100uSec(5000); //delay 500 ms for motor to actually stop

- Flags.current_state = STATE_STARTING;

- }

- break;

- case STATE_STOPPED:

- if(Flags.newCLKW != Flags.CLKW)

- Flags.CLKW = Flags.newCLKW;

- break;

- }

- #ifdef RTDM_DEMO

- DBG_SyncComm(); //assure RTDM communication

- #endif

- }

- return 0;

- }

- /*******************************************************************

- Init_Motor()

- Procedure used to initialize all params for the motor and

- for the AN1160 algorithm.

- Also rotor alignment is done here.

- *******************************************************************/

- void Init_Motor()

- {

- int i; //auxiliary counter

- if(Flags.nb_delay_on == 0) {

- T1CONbits.TON = 0;

- T2CONbits.TON = 0;

- TMR1 = 0;

- TMR2 = 0;

- Flags.TrainPI = 0;

-

- //setting direction CLKW or CCLKW

- if(Flags.CLKW == 1) {

- for(i=0;i<6;i++) {

- PWM_STATE1[i] = PWM_STATE1_CLKW[i];

- PWM_STATE2[i] = PWM_STATE2_CLKW[i];

- PWM_STATE3[i] = PWM_STATE3_CLKW[i];

- MotorPhaseAState[i] = MotorPhaseAState_CLKW[i];

- MotorPhaseBState[i] = MotorPhaseBState_CLKW[i];

- MotorPhaseCState[i] = MotorPhaseCState_CLKW[i];

- ADC_CHANNEL[i] = ADC_CHANNEL_CLKW[i];

- ADC_MASK[i] = ADC_MASK_CLKW[i];

- ADC_XOR[i] = ADC_XOR_CLKW[5-i];

- }

- for(i=0;i<64;i++)

- ADC_BEMF_FILTER[i] = ADC_BEMF_FILTER_CLKW[63-i];

- } else {

- for(i=0;i<6;i++) {

- PWM_STATE1[i] = PWM_STATE1_CLKW[5-i];

- PWM_STATE2[i] = PWM_STATE2_CLKW[5-i];

- PWM_STATE3[i] = PWM_STATE3_CLKW[5-i];

- MotorPhaseAState[i] = MotorPhaseAState_CLKW[5-i];

- MotorPhaseBState[i] = MotorPhaseBState_CLKW[5-i];

- MotorPhaseCState[i] = MotorPhaseCState_CLKW[5-i];

- ADC_CHANNEL[i] = ADC_CHANNEL_CLKW[5-i];

- ADC_MASK[i] = ADC_MASK_CLKW[5-i];

- ADC_XOR[i] = ADC_XOR_CLKW[5-i];

- }

- for(i=0;i<64;i++)

- ADC_BEMF_FILTER[i] = ADC_BEMF_FILTER_CLKW[63-i];

- }

-

- stallCount = 0;

- PIDStructure.qInMeas = STARTUP_RPM;

- PIDStructure.qInRef = STARTUP_RPM;

- InitPI(&PIDStructure,SpeedControl_P,SpeedControl_I,PI_ANTI_WINDUP,MAX_DUTY_CYCLE,MIN_DUTY_CYCLE,0);

- TMR2 = TMR2_MAX; //initialize TMR2 and TMR2 average with the value corresponding to the minimum motor speed

- Timer2Value = TMR2;

- Timer2Average = TMR2;

- Timer1Value = 0;

- Flags.RunMotor = 1; // turn the motor ON

- Flags.Startup = 1; // motor initialized, go to starting sequence

-

- ADCCommState = 5; //always start with sector 6 forced

- //set pwm overdrive to the according PWM channel

- IOCON1 = PWM_STATE1[ADCCommState];

- IOCON2 = PWM_STATE2[ADCCommState];

- IOCON3 = PWM_STATE3[ADCCommState];

- CurrentDuty = STARTUP_DUTY; //Init PWM duty cycle value to minimum duty allowed

- PDC1 = CurrentDuty;

- PDC2 = CurrentDuty;

- PDC3 = CurrentDuty;

- nb_delay = ROTOR_ALIGN_T*PWM_100us_FACTOR*10;

- delay_counter = 0;

- Flags.nb_delay_on = 1;

- t_current = STARTUP_START_T*10; //in ms

- t_sector = 0;

- }

- }

- /**********************************************************************

- Start_Motor()

- Procedure for starting the motor according to the implemented

- startup ramp. After the ramp, PI loop training will begin.

- **********************************************************************/

- void Start_Motor()

- {

- if(Flags.nb_delay_on == 0) { //this is just to test if we're not in a non-blocking delay actually

- if(++ADCCommState>5) // Change The Six-Step Commutation Sector

- ADCCommState = 0;

- AD1CHS0 = ADC_CHANNEL[ADCCommState]; //Change ADC Channel AN Selection

- if(t_current < (unsigned long int)STARTUP_T_RAMP*10) {

- t_sector = STARTUP_SEC_C/t_current; //calculates T for 1 sector, in 100s of uS.

- if(t_sector <= 0) t_sector = 1;

- } else

- if (t_current < ((unsigned int)STARTUP_T_RAMP*10 + STARTUP_T_SUST*10)) {

- Flags.TrainPI = 1;

- AD1CON1bits.SSRC = 3;

- }

- else

- Flags.TrainPI = 0;

- //overdrive and output next motor sector

- IOCON1 = PWM_STATE1[ADCCommState];

- IOCON2 = PWM_STATE2[ADCCommState];

- IOCON3 = PWM_STATE3[ADCCommState];

- //here we want a non-blocking delay for the startup to execute

- nb_delay = t_sector * PWM_100us_FACTOR;

- delay_counter = 0;

- Flags.nb_delay_on = 1;

- t_current += t_sector;

- adcBackEMFFilter = 0; //clear the BEMF filter

- }

- }

- ……………………

- …………限于本文篇幅 余下代码请从51黑下载附件…………

所有资料51hei提供下载:

dsPICDEM MCLV-2开发板用户指南.pdf

(1.18 MB, 下载次数: 51)

dsPICDEM MCLV-2开发板用户指南.pdf

(1.18 MB, 下载次数: 51)

AN1160_dsPIC33EP256MC506_MCLV.rar

(1.04 MB, 下载次数: 67)

AN1160_dsPIC33EP256MC506_MCLV.rar

(1.04 MB, 下载次数: 67)

|